Excellent quality Graphite Mold For Continuous Casting - Graphite Rotor – Ningxin

Excellent quality Graphite Mold For Continuous Casting - Graphite Rotor – Ningxin Detail:

Graphite Rotor

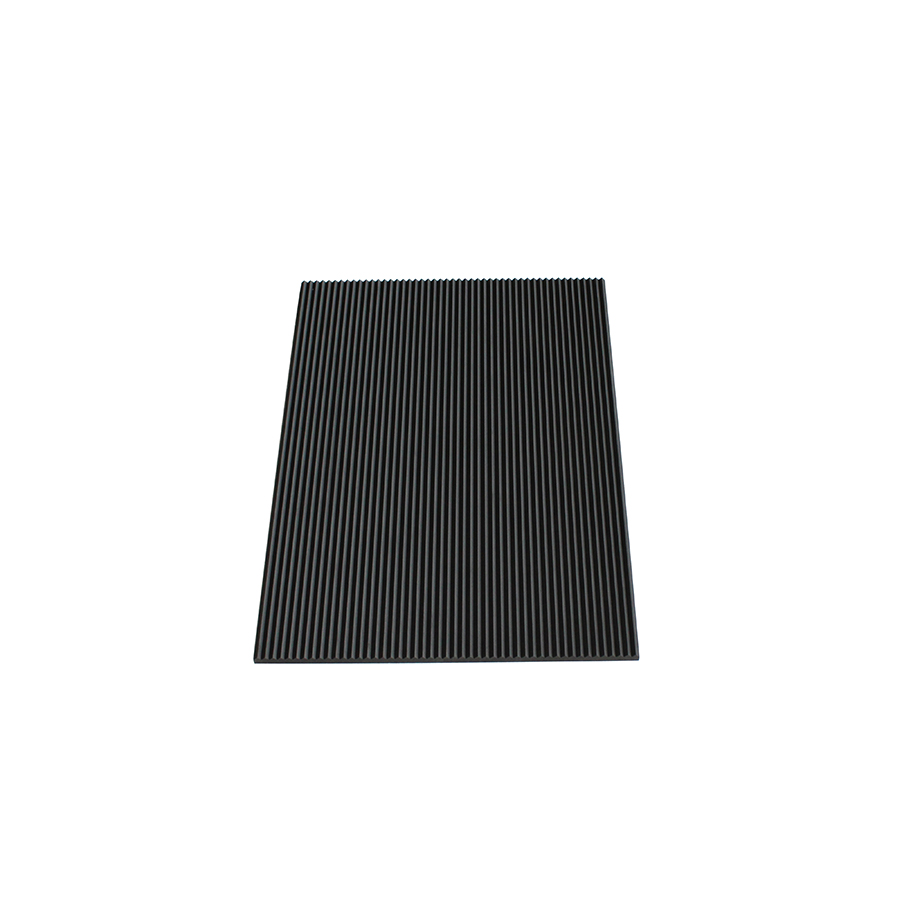

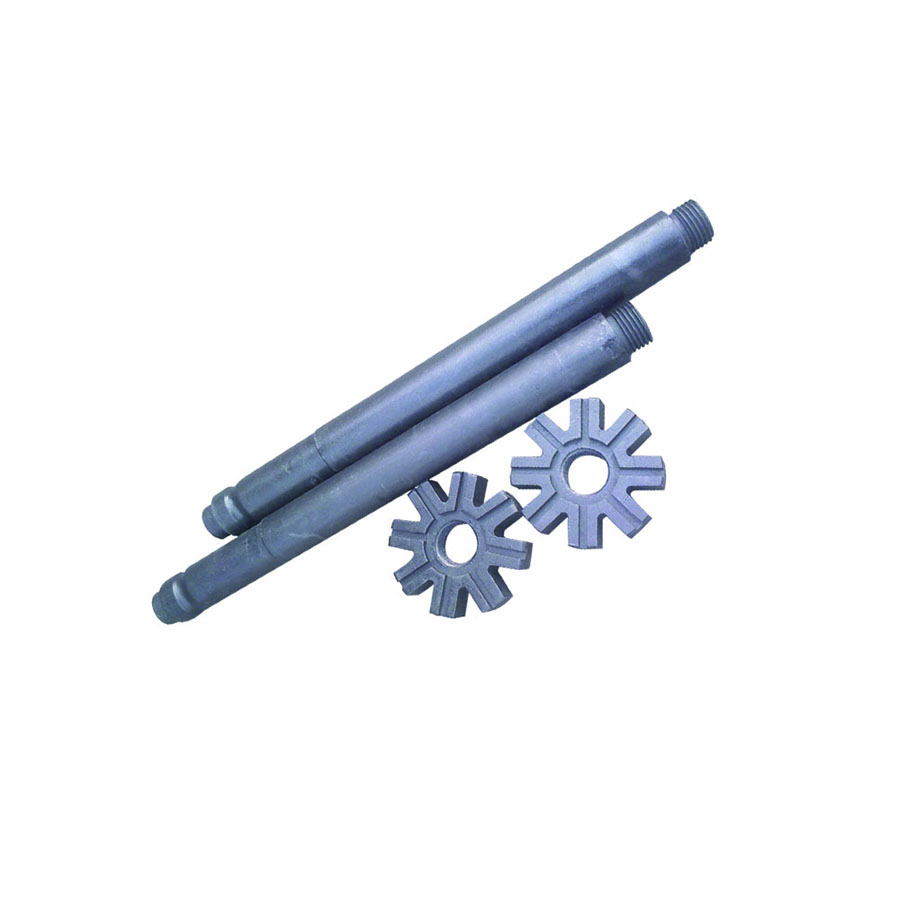

The graphite rotor and graphite impeller are made of high-purity graphite. The surface is treated with special anti-oxidation, and the service life is about 3 times that of ordinary products. It is widely used in aluminum alloy casting industry.

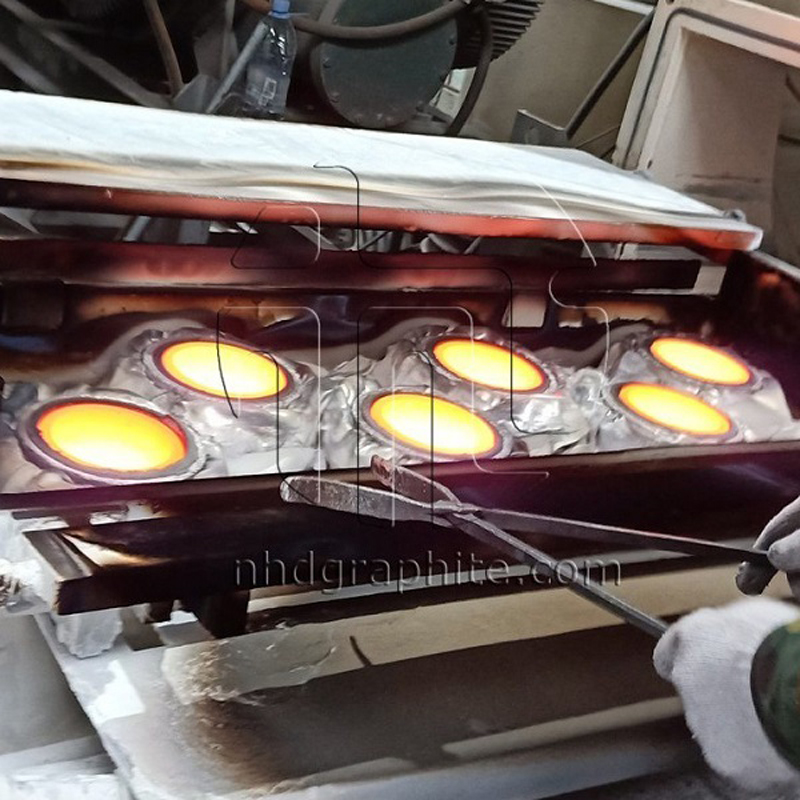

The purification process of liquid aluminum alloy is the main method to improve the comprehensive performance of aluminum alloy. In the purification process, the method of mixing the purification gas and the solvent and spraying the graphite rotor to the aluminum melt for purification is the most advanced treatment method in the world. The working principle of the graphite rotor is: the rotating rotor breaks the nitrogen (or argon) blown into the aluminum melt into a large number of dispersed bubbles and disperses them in the molten metal. Bubbles in the melt rely on the gas partial pressure difference and the principle of surface adsorption to absorb hydrogen in the melt, adsorb oxidized slag, and be taken out of the melt surface as the bubbles rise, so that the melt can be purified. Because the bubbles are small and dispersed, they are evenly mixed with the rotating melt, and then they rotate in a spiral shape to float slowly. The contact time with the melt is long, and the air flow generated by continuous linear rise will not be formed, thereby removing the harmful hydrogen in the aluminum melt. Improved purification effect.

For aluminum alloy foundries and aluminum product factories, it is very important to reduce processing costs. In this regard, the graphite rotors produced by our company can bring the following benefits. 1. Reduce the processing cost 2. Reduce the consumption of inert gas 3. Reduce the aluminum content in the slag 4. Reduce labor costs 5. Improve performance, longer replacement cycle 6. Improve reliability and reduce maintenance costs.

Because the specifications of graphite rotors used in each casting or casting-rolling production line are not the same. First, the customer provides the original design drawings and fills in the complete graphite rotor field use environmental survey form. Then, according to the drawings, combined with the graphite rotor speed, direction of rotation and its relative position to the aluminum liquid level, the technical analysis is carried out, and a suitable anti-erosion resistance is proposed. Oxidation treatment program.

The graphite rotor rotating nozzle is made of high-purity graphite. In addition to considering the need to break up the bubbles, the nozzle structure also uses the centrifugal force generated by stirring the aluminum alloy melt to make the melt enter the nozzle and evenly mix with the horizontally ejected gas to form a gas /The liquid jet is sprayed to increase the contact area and contact time of the bubble and the aluminum alloy liquid, and improve the degassing purification effect.

The speed of the graphite rotor can be steplessly adjusted by the frequency converter speed control, up to 700r/min. The specification of graphite rotor is Φ70mm~250mm, and the specification of impeller is Φ85mm~350mm. The high-purity anti-oxidation graphite rotor has the characteristics of high strength, high temperature resistance, and aluminum flow corrosion resistance. In the process of purifying and degassing, the surface of the aluminum alloy liquid in the box is covered with nitrogen for protection, so that the part of the graphite rotor exposed from the aluminum alloy liquid is in an inert gas to prevent high temperature oxidation of the rotor and prolong the service life of the rotor.

The shape of the impeller is streamlined, which can reduce the resistance during rotation, and the friction and scouring force between the impeller and the aluminum alloy liquid is relatively small. So that the degassing rate is above 50%, shortening the smelting time and reducing the production cost.

Product detail pictures:

Related Product Guide:

Our well-equipped facilities and exceptional good quality manage throughout all stages of production enables us to guarantee total shopper satisfaction for Excellent quality Graphite Mold For Continuous Casting - Graphite Rotor – Ningxin , The product will supply to all over the world, such as: Mauritania, Danish, Gambia, Being the top solutions of our factory, our solutions series have been tested and won us experienced authority certifications. For additional parameters and item list details, be sure to click the button to acquire additional nformation.

Q1. Are you a factory or trading company?

A: We are an ISO9001-Qualified processing manufacturer with 70000 square meter factory area.

Q2. Can you introduce your main products?

A: Sure.

Jiangxi Ningheda New Material Co., Ltd. mainly produces graphite products, we can offer customized shape according to customers’ specific demand. Our Graphite Products, including molded graphite products, isostatic graphite products, extruded graphite products, vibration moulding graphite products. We can produce a lot of graphite products, like graphite mold, graphite casting die, graphite heating element, graphite crucible, graphite sealing ring, graphite tube, graphite rod, graphite edm, graphite block etc.

Q3.What is your MOQ?

A: 1 piece (graphite block, graphite rod, graphite box, graphite mold, graphite material, graphite seal ring, graphite crucible, graphite products, graphite sintering mold, graphite heater etc.).

Q4. Can you offer free samples?

A: Yes, usually we can offer free samples for customers to check the quality, but do not afford express charge.

However, if the sample is expensive, we have to charge basic cost of the sample. And samples delivery time is 3-10 days usually.

Q5. When can I get the price?

A: We will reply you within 24 hours after getting your detailed requirements, like size, quantity etc. If you need an urgent response, pls call us directly.

Q6. Do you accept OEM or ODM orders?

A: Yes, of course, most of our products are customized.

Q7. How about your delivery time?

A: Usually 7 to 25 days after advance payment.

Q8. Do you test your goods before delivery?

A: Yes, we have strict inspection system.

Q9. How do you keep long-term business relationship?

A: 1. Good quality and competitive price to ensure mutual benefit;

2. Quick reply and sincere service.

Remark: When you contact us, please show us the accurate drawing(s) and your selected graphite material information, then we can offer you accurate price(s).

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!