Products

-

Graphite ingot mould

Graphite ingot mold, commonly known as graphite oil tank, is a container used to hold metal liquids such as gold, silver, copper, etc., until the metal liquid is cooled to form a block. The graphite ingot molds of Jiangxi Ningheda New Material Co., Ltd. are usually processed with NX604 or NX605 grade molded graphite, of which bulk density is over 1.85cc, and compressive strength over 65MPa, with long service life and easy demolding, and never contaminating metals.

-

Graphite cave casting mould for gold sliver bar

What is graphite cave casting mould?

The graphite cave casting mould is also called as graphite ingot mold, widely used for casting precious metals, such as gold, silver, copper, jewelry and so on. Jiangxi Ningheda New Material Co., Ltd. is with rich experience in processing graphite products, and is spoken highly of our customers. Customized designs and samples are available.

-

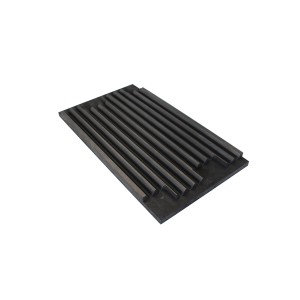

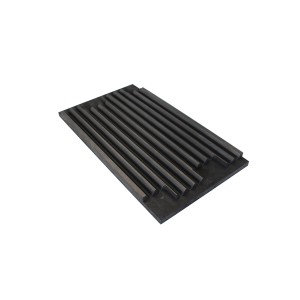

Graphite Roller

What is Graphite Roller?

Graphite roller, produced by Jiangxi Ningheda New Material Co., Ltd., has excellent processing technology, durability, high quality. It has high strength, good thermal shock resistance, high temperature resistance, corrosion resistance, strong oxidation resistance, low impurity content and long service life. It is widely used in the glass fiber industry. Our customers come from well-known glass fiber manufacturers at home and abroad.

-

Graphite parts

Graphite parts are increasingly widely used in vacuum furnaces. They are not only used for heating elements and heat shields for vacuum furnaces, but also for structural parts, such as brackets, trays, guide rails, bolts, bearings, fan blades, etc. The application of graphite in vacuum furnaces greatly simplifies the design and manufacture of vacuum furnaces, reduces the consumption of metals such as tungsten, molybdenum, tantalum, stainless steel, etc., reduces costs, improves certain properties of vacuum furnaces, and expands application field of vacuum furnaces.

Graphite is with good vacuum performance, thermal conductivity, low thermal expansion coefficient, increased strength with increasing temperature, good processing technology, etc., coupled with low cost, so it is a high-quality and low-cost material.

-

Graphite boat graphite plate for tunsgten carbide sintering

Graphite semicircular boat for tunsgten carbide sintering

The graphite boat itself is a kind of carrier, which can put the raw materials and parts that we need to position or shape together in it for high-temperature sintering. The graphite boat is made of artificial graphite through mechanical processing. So it is sometimes called a graphite boat, and sometimes it is called a graphite boat.

Graphite half circle is mainly used in various vacuum resistance furnaces, induction furnaces, sintering furnaces, brazing furnaces, ion nitriding furnaces, tantalum-niobium smelting furnaces, vacuum quenching furnaces, etc.

-

Graphite cluster wheel

Graphite cluster wheel is also known as graphite roller. The graphite cluster wheel produced by Jiangxi Ningheda New Material Co., Ltd. has excellent processing technology, durability, high quality. It has high strength, good thermal shock resistance, high temperature resistance, corrosion resistance, strong oxidation resistance, low impurity content and long service life. It is widely used in the glass fiber industry. Our customers come from well-known glass fiber manufacturers at home and abroad.

-

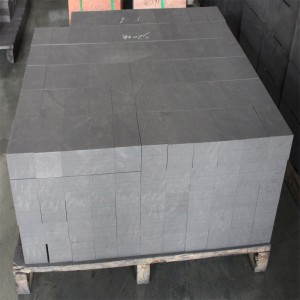

Extruded Graphite

Mid-grained graphite is widely used in the production of poly crystalline silicon in the photovoltaic industry, heating and thermal insulation components in mono crystalline silicon furnaces, and also used in casting, chemical, electronics, non-ferrous metals, high-temperature processing, ceramics and refractory materials and other industries.

-

Graphite Rotor

The graphite rotor and graphite impeller are made of high-purity graphite. The surface is treated with special anti-oxidation, and the service life is about 3 times that of ordinary products. It is widely used in aluminum alloy casting industry.

-

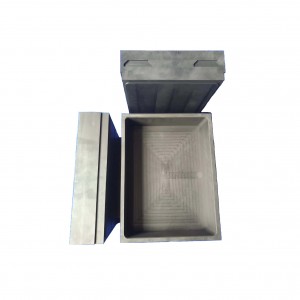

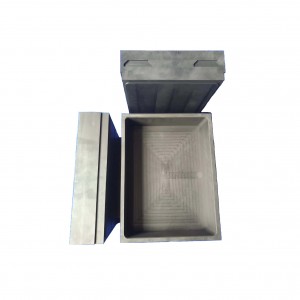

graphite boat

Graphite box (graphite boat) itself is a carrier, we can put the raw materials and parts we need to locate or finalize the design together in which high temperature sintering molding. Graphite box is made of artificial graphite by mechanical processing. So sometimes it’s called a graphite box, sometimes it’s called a graphite boat. The graphite box is mainly used in various vacuum resistance furnaces, induction furnaces, sintering furnaces, brazing furnaces, ion nitridation furnaces, tantalum niobium smelting furnaces, vacuum quenching furnaces, etc.

-

Extruded graphite block for exothermic welding

Technical Characteristic As the material of exothermic welding mold, graphite has the following characteristics: 1) High temperature resistance: The melting point of graphite is 3850±50℃, and the boiling point is 4250℃. Even if burned by ultra-high temperature arc, the weight loss is very small, and the thermal expansion coefficient is also very small. The strength of graphite increases with increasing temperature. At 2000°C, the strength of graphite doubles. The temperature of the chemical r... -

Graphite crucible

This kind of graphite crucible is specially used for aluminum coated film production under vacuum condition. Quality of graphite crucible will greatly affect film quality and production cost. Vacuum evaporation aluminum coating is a process under vacuum condition to coat aluminum onto film substrates to form a composite film. Such as substrates as BOPET, BONY, BOPP, PE, PVC, direct evaporation transferring process usually applied. The vacuum evaporation aluminum coating process requires high quality graphite crucible, and we are capable of stable and quality supplying.

-

Graphite crucible for Aluminum Vacuum Evaporation Coating

The graphite cruicbles are specially used for aluminum coated film production under vacuum condition. Quality of graphite crucible will greatly affect film quality and production cost. Vacuum evaporation aluminum coating is a process under vacuum condition to coat aluminum onto film substrates to form a composite film. Such as substrates as BOPET, BONY, BOPP, PE, PVC, direct evaporation transferring process usually applied. The vacuum evaporation aluminum coating process requires high quality graphite crucible, and we are capable of stable and quality supplying.

-

-

graphite crucible

The graphite rotor and graphite impeller are made of high-purity graphite. The surface is treated with special anti-oxidation, and the service life is about 3 times that of ordinary products. It is widely used in aluminum alloy casting industry.

-

Graphite heater

Graphite heater refers to an electric furnace made of graphite material to heat the heating element part. Graphite has excellent electrical and thermal conductivity properties. Graphite is commonly used as a heating element in special industrial furnaces or electric furnaces. In the early stage of industrial electric furnace, graphite electrodes were used as heating elements, and then high-power electrodes with high density were used as heating elements. With the development of the semiconductor industry, heating furnaces for refining materials such as single crystal silicon, single crystal germanium, gallium arsenide, phosphorous and indium, select high-purity fine-structure graphite and isotropic graphite as heating elements.

-

Graphite crucible

High-purity graphite crucible has good thermal conductivity and high temperature resistance. In high temperature use, the coefficient of thermal expansion is small, and it has a certain resistance to rapid heat and cold. It has strong corrosion resistance to acid and alkali solvents and has good performance. The chemical stability. High-purity graphite crucibles have a wide range of applications, mainly used to smelt various silver, aluminum, lead, copper, zinc and other non-ferrous metals, medium carbon steel and rare metals. The high-purity graphite crucible has stable quality and long service life, greatly reduces fuel consumption, reduces labor intensity, improves labor intensity, and creates better economic benefits.

-

EDM graphite

EDM graphite, also known as graphite for electric discharge machining, is a new type of material, which is now more and more widely used in the precision mold processing industry. At present, in mold processing plants in developed European countries, more than 90% of mold processing electrode materials are graphite. Copper, once the dominant electrode material, has almost disappeared its advantages compared with graphite electrodes. Why is this so? Because graphite has a huge advantage as an electrical discharge material for EDM, since spark oil also contains C atoms, during electrical discharge machining, the high temperature causes the C atoms in the spark oil to be decomposed, thereby forming a protective film on the surface of the EDM graphite electrode , The loss of graphite electrode is compensated, so the loss of graphite electrode is very small, so the service life is long.

-

Graphite mold for continuous casting

Continuous casting graphite mold refers to graphite products used in continuous casting molds. Metal continuous casting technology is a new technology that directly turns molten metal into a material through a continuous casting mold. Because it does not undergo rolling and becomes a material directly, the secondary heating of the metal is avoided, so a lot of energy can be saved.

-

Square graphite boat

Square graphite boat The graphite boat is a kind of graphite mold, using as a carrier, which can put the raw materials and parts that we need to position or shape together in the graphite mold for high-temperature sintering. The graphite mold is made of artificial graphite blocks by mechanical processing. Graphite boats are also called graphite boxes, graphite saggers, and graphite molds. Performance characteristics of graphite boats, graphite boxes and graphite molds for powder metallur... -

Graphite plate

Graphite plate(graphite boat) adopts high-quality graphite material, adding organic compound with strong acid resistance. It is refined by high-pressure forming, vacuum impregnation, and high-temperature heat treatment. It has extraordinary acid and temperature resistance. It is an ideal lining material for phosphoric acid reaction tanks and phosphoric acid storage tanks in the chemical industry. The product has the characteristics of wear resistance, temperature resistance, pressure resistance, corrosion resistance, creep resistance, oil-free self-lubrication, small expansion coefficient, and superior sealing performance.

-

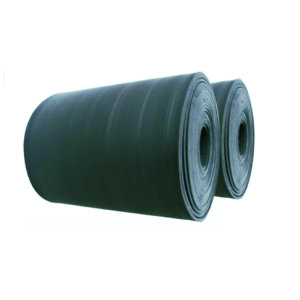

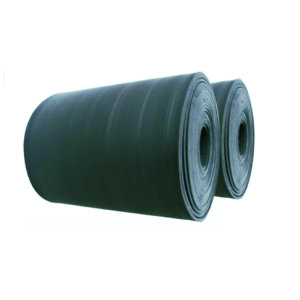

Graphite felt

Graphite felt is divided into pitch-based graphite felt, polyacrylonitrile-based (PAN-based) graphite felt, and viscose-based graphite felt due to the different selection of original felts. The main purpose is to be used as heat preservation and heat insulation materials for monocrystalline silicon smelting furnaces. In the chemical industry, it can be used as a filter material for high-purity corrosive chemical reagents.

Carbon felt is graphite felt after being treated at a high temperature of over 2000℃ under vacuum or inert atmosphere. The carbon content is higher than that of carbon felt, reaching more than 99%. At the end of the 1960s, graphite felt was already available in the world. Graphite felt is divided into pitch-based, polyacrylonitrile-based graphite felt and viscose-based graphite felt due to the different selection of the original felt.

-

Graphite Boat for Lithium iron phosphate battery

Graphite boat(graphite sagger) itself is a carrier, we can put the raw materials and parts we need to locate or finalize the design together in which high temperature sintering molding. Graphite boat is made of artificial graphite by mechanical processing. So sometimes it’s called a graphite boat, sometimes it’s called a graphite box. The graphite boat is mainly used in various vacuum resistance furnaces, induction furnaces, sintering furnaces, brazing furnaces, ion nitridation furnaces, tantalum niobium smelting furnaces, vacuum quenching furnaces, etc.

-

Graphite Box for anode powder

Graphite box (graphite boat) itself is a carrier, we can put the raw materials and parts we need to locate or finalize the design together in which high temperature sintering molding. Graphite box is made of artificial graphite by mechanical processing. So sometimes it’s called a graphite box, sometimes it’s called a graphite boat. The graphite box is mainly used in various vacuum resistance furnaces, induction furnaces, sintering furnaces, brazing furnaces, ion nitridation furnaces, tantalum niobium smelting furnaces, vacuum quenching furnaces, etc.

-

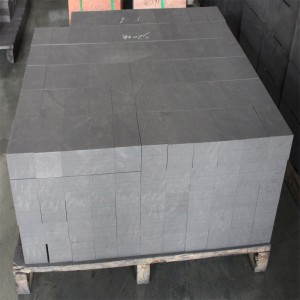

Molded Graphite

The fine grain graphite block produced by cold molding is widely used in machinery, electronics, semiconductors, polycrystalline silicon, monocrystalline silicon, metallurgy, chemical, textile, electric furnaces, space technology and biological and chemical industries.

The graphite has the following characteristics:

- Good electric conductivity and high thermal conductivity

- Low thermal expansion and high resistance to thermal shock.

- The strength increases at high temperature, and it can withstand over 3000 degrees.

- Stable chemical property and hard to react

- Self lubrication

- Easy to process

-

Isostatic graphite

Isostatic graphite refers to graphite materials produced by isostatic pressing. Isostatic graphite is pressed uniformly by liquid pressure during the molding process, and the obtained graphite material has excellent properties. It has: large molding specifications, uniform blank structure, high density, high strength, and isotropy (characteristics and dimensions, The shape and sampling direction are irrelevant) and other advantages, so isostatic graphite is also called “isotropic” graphite.