Hot-selling Copper Alloy Smelting Crucibles - graphite crucible – Ningxin

Hot-selling Copper Alloy Smelting Crucibles - graphite crucible – Ningxin Detail:

Graphite Crucible

High-purity graphite has the characteristics of high strength, high density, high purity, high chemical stability, compact and uniform structure, high temperature resistance, high electrical conductivity, good wear resistance, self-lubricating, and easy processing. It is widely used in metallurgy, chemical industry, and aerospace. , Electronics, machinery, nuclear energy and other industrial fields. Especially large-scale and high-quality high-purity graphite, as an alternative material, has a broad application space in high-tech and new technology fields, and has a wide range of application prospects.

High-purity graphite crucible has excellent thermal stability, corrosion resistance, impact resistance, acid corrosion resistance, high thermal conductivity and quality stability. It is a kind of very excellent performance in molten gold crucibles, and is currently widely used in alloy tools The smelting of steel and the smelting of non-ferrous metals and their alloys. However, improper use of high-purity graphite crucibles will greatly affect its performance and service life.

Therefore, relevant experts have summarized the following points for the use of high-purity graphite crucibles

1: The high-purity graphite crucible must be slowly baked to 500 degrees Celsius before use. After use, it must be placed in a dry place to avoid water intrusion.

2: When using, it must be added according to the capacity of the high-purity graphite crucible, and the metals placed should not be squeezed too tightly to prevent the metal from thermally expanding and cracking the crucible.

3: When taking out the molten metal after melting, it is best to scoop it out with a spoon, use calipers as little as possible, and pay attention to the action to be light, to avoid impacting the crucible to excessive force and damage.

4: When using high-purity graphite crucible, avoid strong oxidizing flame directly spraying on the crucible wall, which will damage the crucible and shorten the service life.

The high-purity graphite crucible has excellent performance, but in order to better use and prolong the service life of the high-purity graphite crucible, we must know the above instructions to avoid damaging it.

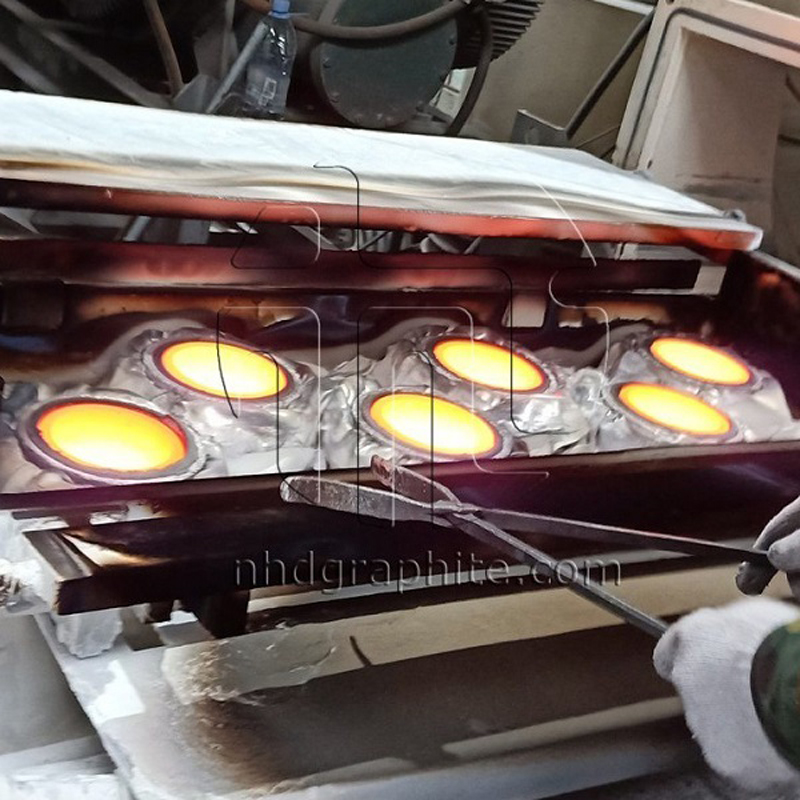

Product detail pictures:

Related Product Guide:

We normally believe that one's character decides products' quality, the details decides products' high-quality ,while using the REALISTIC,EFFICIENT AND INNOVATIVE staff spirit for Hot-selling Copper Alloy Smelting Crucibles - graphite crucible – Ningxin , The product will supply to all over the world, such as: Malaysia, Finland, Puerto Rico, Our company always concentrate on the development of the international market. We've got a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

Q1. Are you a factory or trading company?

A: We are an ISO9001-Qualified processing manufacturer with 70000 square meter factory area.

Q2. Can you introduce your main products?

A: Sure.

Jiangxi Ningheda New Material Co., Ltd. mainly produces graphite products, we can offer customized shape according to customers’ specific demand. Our Graphite Products, including molded graphite products, isostatic graphite products, extruded graphite products, vibration moulding graphite products. We can produce a lot of graphite products, like graphite mold, graphite casting die, graphite heating element, graphite crucible, graphite sealing ring, graphite tube, graphite rod, graphite edm, graphite block etc.

Q3.What is your MOQ?

A: 1 piece (graphite block, graphite rod, graphite box, graphite mold, graphite material, graphite seal ring, graphite crucible, graphite products, graphite sintering mold, graphite heater etc.).

Q4. Can you offer free samples?

A: Yes, usually we can offer free samples for customers to check the quality, but do not afford express charge.

However, if the sample is expensive, we have to charge basic cost of the sample. And samples delivery time is 3-10 days usually.

Q5. When can I get the price?

A: We will reply you within 24 hours after getting your detailed requirements, like size, quantity etc. If you need an urgent response, pls call us directly.

Q6. Do you accept OEM or ODM orders?

A: Yes, of course, most of our products are customized.

Q7. How about your delivery time?

A: Usually 7 to 25 days after advance payment.

Q8. Do you test your goods before delivery?

A: Yes, we have strict inspection system.

Q9. How do you keep long-term business relationship?

A: 1. Good quality and competitive price to ensure mutual benefit;

2. Quick reply and sincere service.

Remark: When you contact us, please show us the accurate drawing(s) and your selected graphite material information, then we can offer you accurate price(s).

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!