Massive Selection for Sintered Boat For Hard Alloy - Well-designed China Isostatic Graphite for Heat Element – Ningxin

Massive Selection for Sintered Boat For Hard Alloy - Well-designed China Isostatic Graphite for Heat Element – Ningxin Detail:

we are able to supply top quality items, aggressive price and greatest buyer assistance. Our destination is “You come here with difficulty and we offer you a smile to take away” for Well-designed China Isostatic Graphite for Heat Element, We sincerely welcome both foreign and domestic business partners, and hope to work with you in the near future!

we are able to supply top quality items, aggressive price and greatest buyer assistance. Our destination is “You come here with difficulty and we offer you a smile to take away” for China EDM, Isostatic Graphite, Profession, Devoting are always fundamental to our mission. Now we have always been in line with serving customers, creating value management objectives and adhering to the sincerity, dedication, persistent management idea.

Features of isostatic pressing technology

(1) The density of isostatic pressing products is high, which is generally 5%-15% higher than that of unidirectional and two-way molding. The relative density of hot isostatic pressing products can reach 99.80%-99.99%.

(2) The density of the compact is uniform. In compression molding, whether it is one-way or two-way pressing, the green compact density distribution will be uneven. This density change can often reach more than 10% when pressing products with complex shapes. This is caused by the frictional resistance between the powder and the steel mold. Isostatic fluid media transfer pressure, equal in all directions. The compression of the envelope and the powder is roughly the same. There is no relative movement between the powder and the envelope. There is little frictional resistance between them, and the pressure drops only slightly. The density drop gradient is generally less than 1%. Therefore, it can be considered that the blank The bulk density is uniform.

(3) Because of the uniform density, the production aspect ratio can be unlimited, which is conducive to the production of rod-shaped, tubular, thin and long products.

(4) The isostatic pressing molding process generally does not need to add lubricant to the powder, which not only reduces the pollution to the product, but also simplifies the manufacturing process.

(5) Isostatically pressed products have excellent performance, short production cycle and wide application range.

(6) The disadvantage of the isostatic pressing process is that the process efficiency is low and the equipment is expensive.

Characteristics of isostatic graphite materials

(1) Isotropic

Generally, materials with an isotropy degree of 1.0 to 1.1 are called isotropic materials. Due to the isostatic pressing, the isotropy of isostatic graphite can be within 1.0 to 1.1. The isotropy of isostatic graphite is affected by the heat treatment process, the isotropy of the powder particles and the molding process.

In the heat treatment process of isostatic graphite, heat is gradually transferred from the outside to the inside, and the temperature is gradually reduced from the outside to the inside. The uniformity of the external temperature is better than the uniformity of the internal temperature. Homotropy is better than internal.

After the binder pitch is graphitized, the microcrystalline structure formed has little effect on the isotropy of the graphite block. If the isotropy of the powder particles is good, even if the compression molding is used, the isotropy can be prepared. Graphite with good homogeneity.

In terms of molding process, if the binder pitch and powder are not uniformly kneaded, it will also affect the isotropy of the isostatic graphite.

(2) Large size and fine structure

It is impossible to prepare carbon products with large specifications and fine structures by compression molding. To a certain extent, isostatic pressing can overcome the shortcomings of uneven product volume density caused by compression molding, greatly reduce the probability of product cracking, and make the production of large-size and fine-structure products a reality.

(3) Homogeneity

The internal structure of isostatic graphite is relatively uniform, and the bulk density, resistivity and strength of each part are not much different. It can be regarded as a homogeneous graphite material. The homogeneity of isostatic graphite is determined by the pressing method of isostatic pressing. When isostatic pressing is used, the pressure transmission effect along the pressing direction is the same, so the volume density of each part of the isostatic pressing graphite is uniform.we are able to supply top quality items, aggressive price and greatest buyer assistance. Our destination is “You come here with difficulty and we offer you a smile to take away” for Well-designed China Isostatic Graphite for Heat Element, We sincerely welcome both foreign and domestic business partners, and hope to work with you in the near future!

Well-designed China EDM, Graphite, Profession, Devoting are always fundamental to our mission. Now we have always been in line with serving customers, creating value management objectives and adhering to the sincerity, dedication, persistent management idea.

Alisa Deng alisa@nhdcarbon.com +86-18370509070

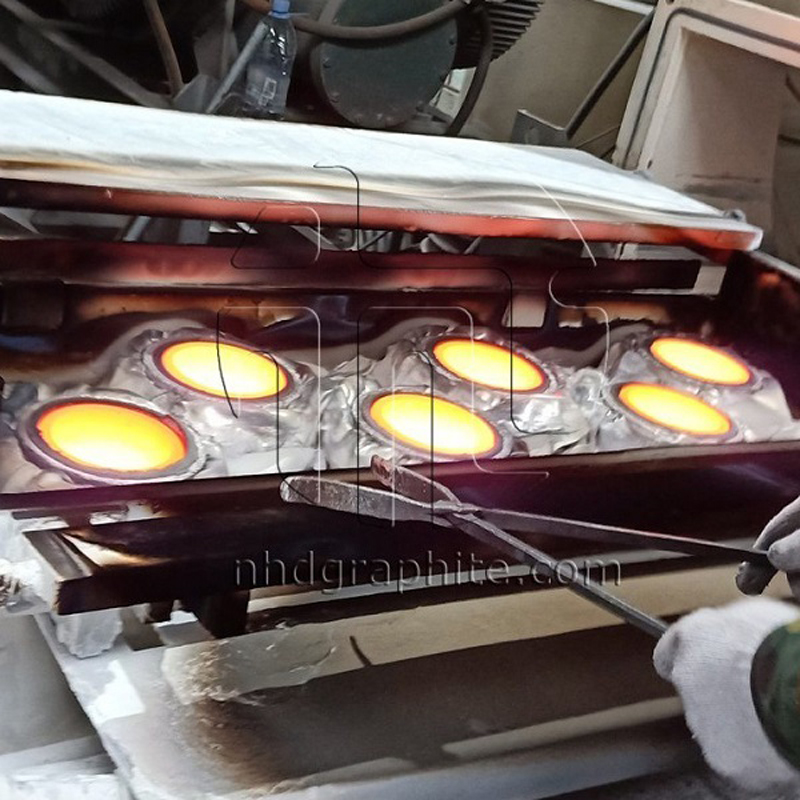

Product detail pictures:

Related Product Guide:

With our superb management, potent technical capability and strict quality command procedure, we go on to provide our shoppers with trustworthy high-quality, reasonable costs and outstanding services. We goal at becoming considered one of your most trustworthy partners and earning your pleasure for Massive Selection for Sintered Boat For Hard Alloy - Well-designed China Isostatic Graphite for Heat Element – Ningxin , The product will supply to all over the world, such as: Mombasa, Rotterdam, Zimbabwe, We have many years' experience in hair product production, and our strict QC Team and skilled workers will ensure that we give you top hair products with the best hair quality and workmanship. You will get successful business if you choose to cooperate with such a professional manufacturer. Welcome your order cooperation!

Q1. Are you a factory or trading company?

A: We are an ISO9001-Qualified processing manufacturer with 70000 square meter factory area.

Q2. Can you introduce your main products?

A: Sure.

Jiangxi Ningheda New Material Co., Ltd. mainly produces graphite products, we can offer customized shape according to customers’ specific demand. Our Graphite Products, including molded graphite products, isostatic graphite products, extruded graphite products, vibration moulding graphite products. We can produce a lot of graphite products, like graphite mold, graphite casting die, graphite heating element, graphite crucible, graphite sealing ring, graphite tube, graphite rod, graphite edm, graphite block etc.

Q3.What is your MOQ?

A: 1 piece (graphite block, graphite rod, graphite box, graphite mold, graphite material, graphite seal ring, graphite crucible, graphite products, graphite sintering mold, graphite heater etc.).

Q4. Can you offer free samples?

A: Yes, usually we can offer free samples for customers to check the quality, but do not afford express charge.

However, if the sample is expensive, we have to charge basic cost of the sample. And samples delivery time is 3-10 days usually.

Q5. When can I get the price?

A: We will reply you within 24 hours after getting your detailed requirements, like size, quantity etc. If you need an urgent response, pls call us directly.

Q6. Do you accept OEM or ODM orders?

A: Yes, of course, most of our products are customized.

Q7. How about your delivery time?

A: Usually 7 to 25 days after advance payment.

Q8. Do you test your goods before delivery?

A: Yes, we have strict inspection system.

Q9. How do you keep long-term business relationship?

A: 1. Good quality and competitive price to ensure mutual benefit;

2. Quick reply and sincere service.

Remark: When you contact us, please show us the accurate drawing(s) and your selected graphite material information, then we can offer you accurate price(s).

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.