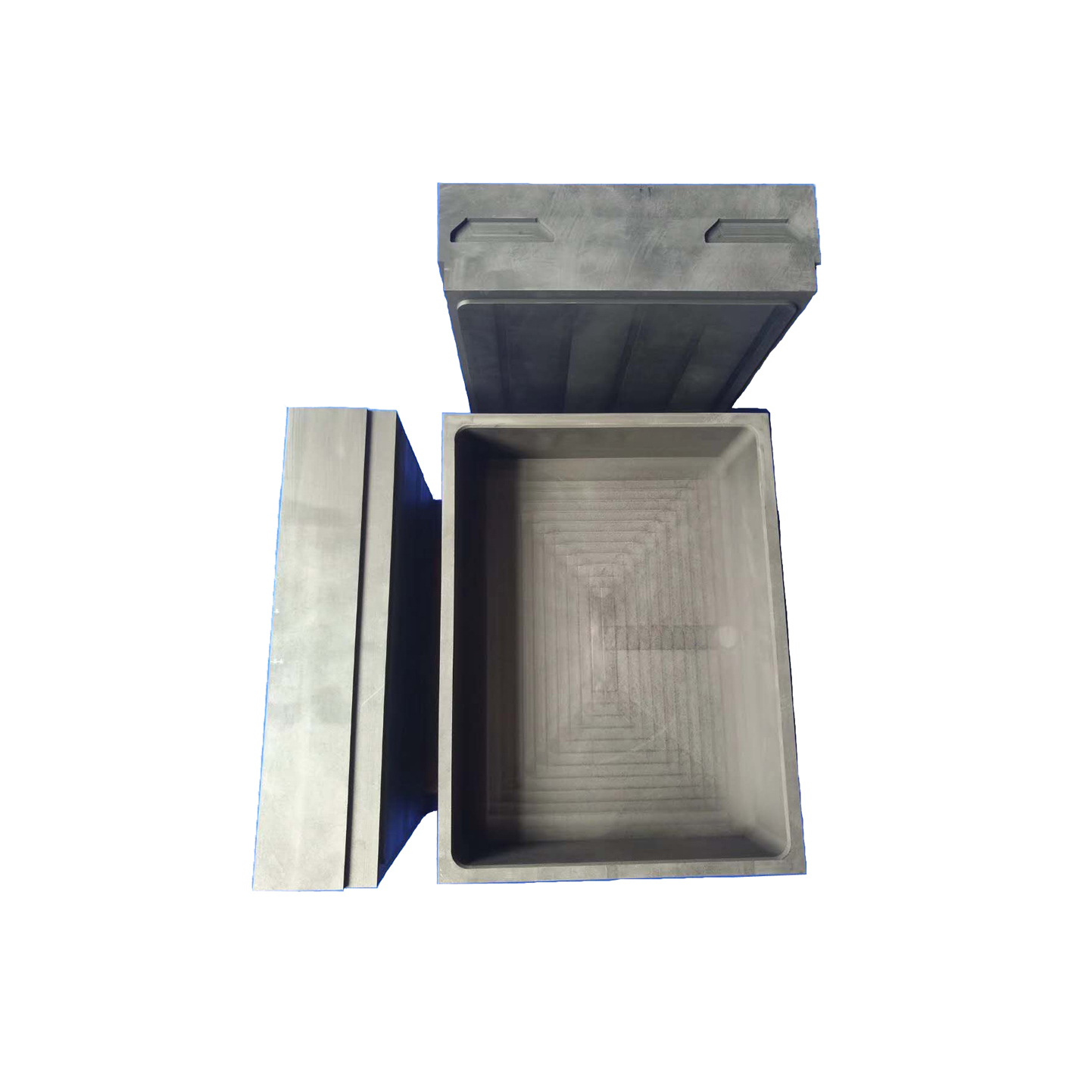

Graphite Box for anode powder

Our advantage

1. Thermal stability: for the use of hot and cold conditions, special treatment to ensure the reliability of product quality.

2. Corrosion resistance: uniform and fine material structure, delay the erosion of the use of degrees.

3. impact resistance: the ability to withstand high thermal shock, so the process can be assured.

4.Acid resistance: the addition of special materials significantly improved the physical properties of the material, excellent performance in terms of acid resistance, and greatly extend the service life of graphite.

5. High thermal conductivity: high content of fixed carbon ensures good thermal conductivity, shortens dissolution time, and significantly reduces energy consumption.

6. Pollution control: strict control of the material composition, to ensure that the pollution of the material greatly reduced.

7. Quality stability: uniform static pressing forming technology, process and quality control system more fully ensure the stability of the material.

8. Advanced processing technology, tolerance and appearance are better than customer standards;

9. With professionals who are familiar with customers' related industries, they can provide professional customization and supporting services.

Precautions when using graphite box:

1. The columns of the graphite box must be vertical and stable: the columns of the graphite box must be supported by fire-resistant clips to prevent them from swaying at high temperatures. The graphite box column on the outer ring shall not be inclined to the kiln wall, but may be slightly inclined to the center of the kiln.

2. After filling the kiln, seal the kiln door: the kiln door should preferably be built with refractory bricks on the inner and outer layers. The inner layer should be flush with the inner wall of the kiln wall, and the outer layer should be flush with the outer wall of the kiln wall, and each layer should be painted. Fire clay. When building the kiln door, leave a fire observation hole, and the position of the fire observation hole should be fixed every time the kiln is installed to avoid sudden high and low, large and small, which will affect the correct temperature measurement.

3. The height of the graphite box column: it should be determined according to the kiln structure and the temperature rise of various parts in the kiln. In general, the graphite box column near the vent should be lower to reduce the resistance of the flame to rise. Although the graphite box column in the middle can be taller, there should be enough space between the top of the kiln and the rising flames to converge here, and then redistribute them to the fire channels of the fire absorbing holes.

Packing & Delivery

Packaging: export standard wooden case.

Delivery Detail: 15~30 working days after confirming order.

Sea Port: Shanghai or other port of China Mainland.

Q1. Are you a factory or trading company?

A: We are an ISO9001-Qualified processing manufacturer with 70000 square meter factory area.

Q2. Can you introduce your main products?

A: Sure.

Jiangxi Ningheda New Material Co., Ltd. mainly produces graphite products, we can offer customized shape according to customers’ specific demand. Our Graphite Products, including molded graphite products, isostatic graphite products, extruded graphite products, vibration moulding graphite products. We can produce a lot of graphite products, like graphite mold, graphite casting die, graphite heating element, graphite crucible, graphite sealing ring, graphite tube, graphite rod, graphite edm, graphite block etc.

Q3.What is your MOQ?

A: 1 piece (graphite block, graphite rod, graphite box, graphite mold, graphite material, graphite seal ring, graphite crucible, graphite products, graphite sintering mold, graphite heater etc.).

Q4. Can you offer free samples?

A: Yes, usually we can offer free samples for customers to check the quality, but do not afford express charge.

However, if the sample is expensive, we have to charge basic cost of the sample. And samples delivery time is 3-10 days usually.

Q5. When can I get the price?

A: We will reply you within 24 hours after getting your detailed requirements, like size, quantity etc. If you need an urgent response, pls call us directly.

Q6. Do you accept OEM or ODM orders?

A: Yes, of course, most of our products are customized.

Q7. How about your delivery time?

A: Usually 7 to 25 days after advance payment.

Q8. Do you test your goods before delivery?

A: Yes, we have strict inspection system.

Q9. How do you keep long-term business relationship?

A: 1. Good quality and competitive price to ensure mutual benefit;

2. Quick reply and sincere service.

Remark: When you contact us, please show us the accurate drawing(s) and your selected graphite material information, then we can offer you accurate price(s).