Our Graphite Mold for Diamond Coring Bits is manufactured using the finest quality graphite rod that is known for its superior strength, durability, and heat resistance. The mold is designed to create coring bits with high precision and accuracy, ensuring that each bit is of the highest quality and can deliver the best results.

The Graphite Mold is a versatile tool that can be used to make a variety of diamond coring bits, including bits for exploration drilling, mining and construction, water wells, and oil and gas drilling. It is designed to create bits of varying diameters and lengths, which can be customized to meet the specific requirements of your project.

Our Graphite Mold for Diamond Coring Bits is easy to use, and its simple design ensures that it can be used by both seasoned professionals and beginners alike. To create a coring bit, all you need to do is pour molten metal into the mold and allow it to cool. Once the metal has hardened, the coring bit can be removed from the mold and used in your drilling operations.

The Graphite Mold for Diamond Coring Bits is an eco-friendly product that does not pose any health or environmental hazards. The graphite rod used in the mold is a natural and sustainable material that can be recycled, ensuring that it does not end up in landfills or contribute to pollution.

Our Graphite Mold for Diamond Coring Bits is not just a tool, it is an investment that can help you save time, money and effort in your drilling operations. By using high-quality coring bits made from our mold, you can increase productivity, reduce downtime, and minimize the need for frequent bit replacement.

In conclusion, our Graphite Mold for Diamond Coring Bits is the perfect solution for those looking for high-quality and reliable coring bits that can withstand the toughest drilling conditions. With its superior quality and durability, it is the ideal tool for professionals in the drilling industry who demand nothing but the best. Contact us today to learn more about our Graphite Mold for Diamond Coring Bits and how it can benefit your drilling operations.

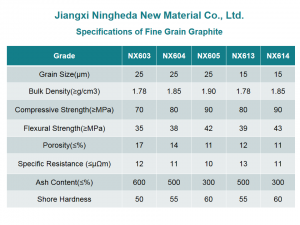

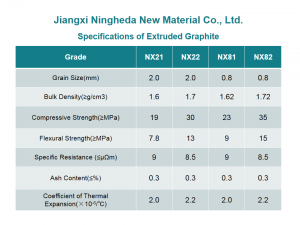

Specifications of graphite:

Advantages of Ningheda graphite raw material

1. The processing materials are ultrafine granule structure, high purity and graphite with high graphitization degree.

2. High hardness, good anti-oxidation performance and high machining accuracy

3. Good conductivity, high resistivity, sufficient mechanical strength

4. Small porosity and dense structure.

5. Excellent thermal shock resistance, conductive and thermal conductivity.

6. High temperature resistance, corrosion resistance, acid and alkali resistance, good wear resistance.

7. Surface can be treated with anti-oxidation.

Post time: May-30-2023