The continuous casting process for non-ferrous metals has been making waves in the manufacturing industry. Despite the traditional use of ingot casting, the continuous casting process has become the preferred choice for many manufacturers of non-ferrous metals due to its benefits.

Continuous casting is a process where molten metal is poured into a tundish and then fed through a water-cooled die where it solidifies into a continuous billet or slab. Compared to ingot casting, this method is faster, more efficient, and produces a greater yield of quality metal.

Non-ferrous metals like copper, aluminum and zinc are ideal for continuous casting and can be used in a range of applications from electrical wires to car components. The process allows for better control of the metal structure resulting in stronger and more homogeneous material.

The demand for non-ferrous metals has been increasing steadily in many sectors, including construction, transportation, and electronics. The continuous casting process has helped meet this demand by increasing production efficiency while lowering production costs.

The success of continuous casting for non-ferrous metals has sparked research into other forms of casting processes for unreinforced metals. New methods have been developed to create strands utilizing this technique. Stranded wires made by the continuous casting process have increased mechanical strength, conductivity, and potential for temperature and wear resistance.

Continuous casting is capable of producing a range of non-ferrous metal billets, rods, tubes, and profiles. This technology has led to better quality non-ferrous materials and new product development to meet customer needs in a more cost-effective and timely manner.

With the continuous casting process, non-ferrous metal manufacturers have seen an improvement in the production process, product quality, and cost-efficiency. As a result, more and more industries are moving towards this method of casting to enjoy the benefits it offers.

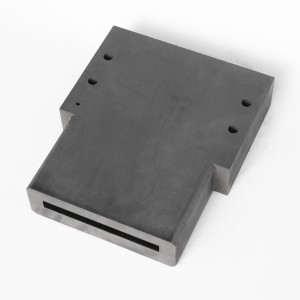

We supply kinds of graphite products for continuous casting, such as graphite crucible, graphite ingot mould, graphite mould, graphite stirring rod etc.

Post time: May-24-2023